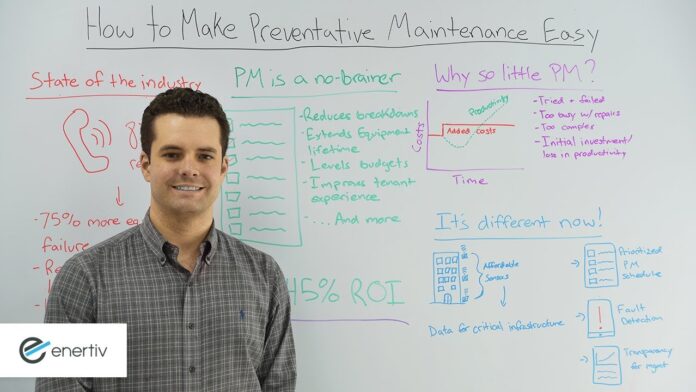

How to Make Preventative Maintenance Easy

Các câu hỏi, thắc mắc, thông tin liên quan đến sản phẩm được giới thiệu trong video dưới đây từ khâu mua sắm, lựa chọn, sử dụng, cài đặt hay thay thế, vui lòng liên hệ với INO Team để được hỗ trợ và tư vấn kịp thời.

– – – LƯU Ý – – -: Với những thiết bị không được liệt kê ở đây không có nghĩa là chúng tôi không hỗ trợ được bạn, công ty chúng tôi chuyên đề xuất giải pháp, tư vấn mua sắm và cung cấp thiết bị về cảm biến công nghiệp, đo lường và tự động hoá cho các công ty trong và ngoài nước.

Công ty TNHH Giải pháp và Công nghệ Đo lường INO, nhà cung cấp các thiết bị đo lường và tự động hóa công nghiệp.

Video Transcription

Hi I’m Connell, the Co-Founder and CEO of Enertiv. Today I want to talk about preventative maintenance and why, if your portfolio does not have a preventative maintenance strategy in place, you might want to reconsider.

But don’t worry, you’re not alone: over 87% of maintenance is completely reactive. This isn’t good. It leads to 75% more equipment failures, it reduces equipment lifetime by as much as 36%, your budgets become unpredictable, and you have a lot more tenant complaints.

Preventative maintenance, where you have a schedule and you’re regularly adjusting and maintaining individual pieces of equipment in your buildings is really a no brainer.

You’re going to have reduced equipment breakdowns, it’s going to extend the lifetime of all of your equipment, it’ll level out your budgets and you’re going to have far less tenant complaints.

The best part of all is that studies have shown recently that preventative maintenance can deliver as high as a 545% return on investment.

So why aren’t more companies doing preventative maintenance? Well, some have tried and failed, some are just too busy with repairs and putting out fires to keep their tenants happy, some think it’s too complicated or don’t have the internal resources to put a plan in place, and lastly this piece is important, some are just concerned about the initial investment.

I don’t want to sugar coat this. There certainly are some added costs and productivity will take a hit initially, but in the long run, it’s going to pay for itself over and over again.

The good news is, it’s gotten even easier to adopt a preventative maintenance strategy. There are new technologies today that can study how each piece of equipment in a building is performing. With that data, it can basically tell building operators when to look at specific pieces of equipment and what adjustments need to be made to avoid much larger equipment failures down the road.

These systems can also predict and detect when major pieces of equipment are going to fail. If this happens, operators are notified right away, and showed exactly where that equipment is located, how it’s powered, how to fix it, and what to do in order to get it back on line as quickly as possible.

The last piece, and this is important if you’re an owner who’s considering adopting a new technology like this, you’re going to have full transparency into all the equipment-level issues that you have in your building and across your portfolio of buildings. You’ll be able to see how quickly your on-site team is responding to these instances in an effort to improve your tenants’ experience.

I’d love to keep this conversation going, if you have questions, please comment below and have a great weekend.

If you’re interested in using technology to create and/or optimize a preventative maintenance strategy, schedule a demo to see how Enertiv does it today.

Web: www.ino.com.vn | Mail: info@ino.com.vn

Tel: (+84) 028 73000184 | Hotline: 0947200184

Website: http://www.ino.com.vn Website: http://www.ino.vn

Please visit INO YouTube Channel for more Video

https://www.youtube.com/inomeasure